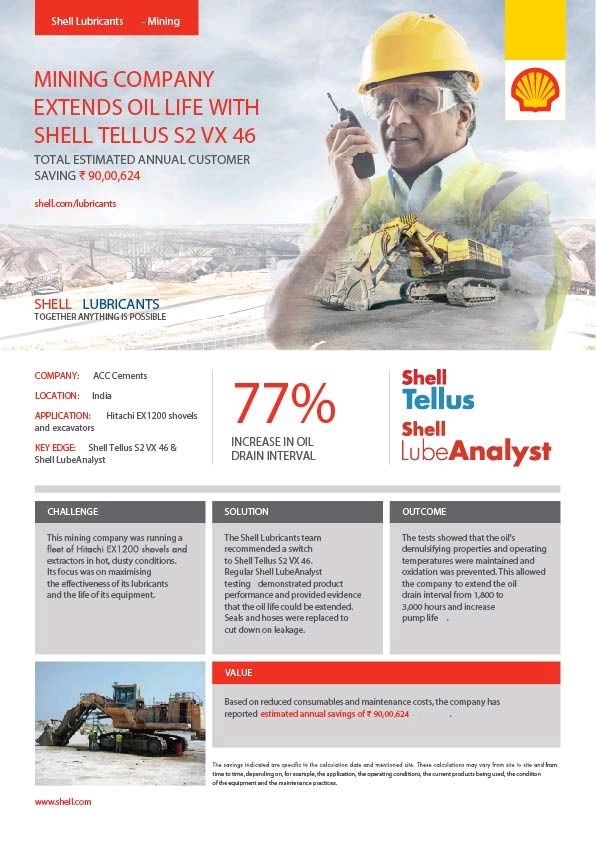

Mining Company Extends Oil Life With Shell Tellus S2 VX 46

Mining Company Extends Oil Life With Shell Tellus S2 VX 46

COMPANY – ACC Cements

LOCATION – India

APPLICATION – Hitachi EX 1200 shovels and excavators

KEY EDGE – ShellTellus S2 VX 46 & Shell LubeAnalyst

SIGNIFICANT – 77% Increase in oil drain interval

CHALLENGE – This mining company was running a fleet of Hitachi EX 1200 shovels and extractors in hot, dusty conditions. Its focus was on maximising the effectiveness of its lubricants and the life of its equipment.

SOLUTIONS – The Shell Lubricants team recommended a switch to Shell Tellus S2 VX 46. Regular Shell LubeAnalyst testing demonstrated product performance and provided evidence that the oil life could be extended. Seals and hoses were replaced to cut down on leakage.

OUTCOME – The tests showed that the oil’s demulsifying properties and operating temperatures were maintained and oxidation was prevented. This allowed the company to extend the oil drain interval from 1,800 to 3,000 hours and increase pump life.

Based on reduced consumables and maintenance costs, the company has reported estimated annual savings of ₹ 90,00,624.